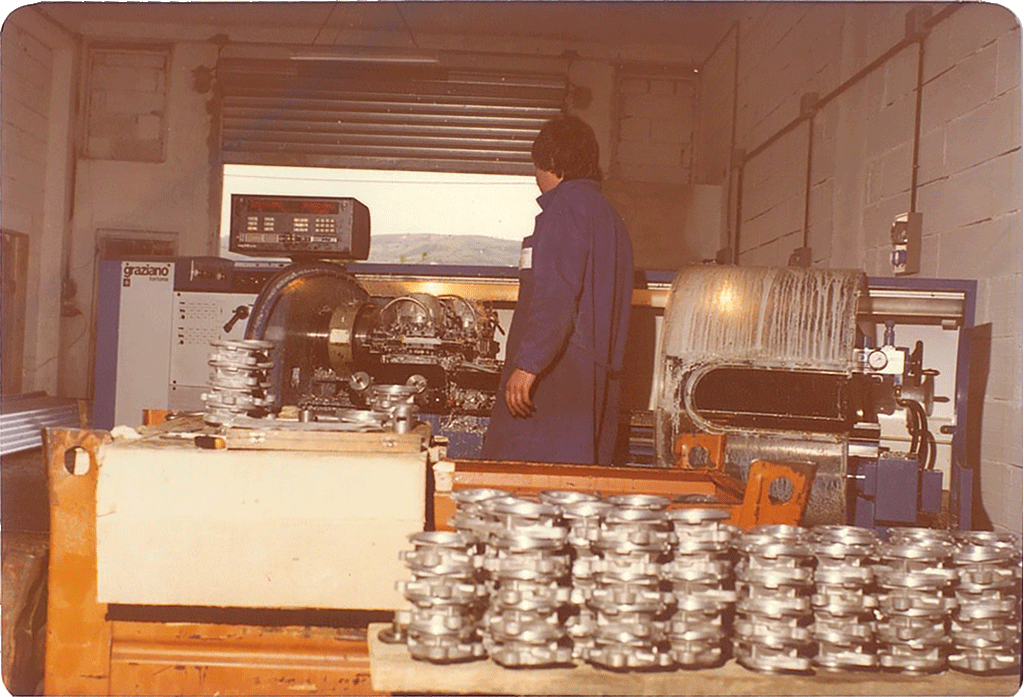

For over 40 years C.T. Centro Tornitura has been performing precision machining by chip-removal for the automotive and industrial sector.

The company was born from

the commitment of the founder Antonio Frungieri, who, after the experience gained at Fiat and other mechanical companies in Turin, in 1977 started his entrepreneurial activity in Potenza (Basilicata).

In 1991, C.T. Centro Tornitura, to meet the growing production and innovation needs, has moved its production activity in Tito Scalo, near Potenza, in a factory of around 3,000 square meters capable of hosting a modern and diversified machinery equipment.

Precision machining is carried out mainly on die-cast aluminum and steel components.

The company directly manages the entire production process, at every stage until delivery to the customer, including prototyping, product engineering, choice of suppliers, purchase of raw materials, mechanical processing, washing, assembly of components and heat and / or galvanic treatments, carried out by reliable external partners.

Over the decades of activity, C.T. Centro Tornitura has expanded and renewed the production department, now consisting of numerous numerical control machining centers and lathes, transfer machines and washing stations, with which it is able to guarantee a large production capacity, flexibility, compliance with delivery times and a high quality of products and services.

C. T. Centro Tornitura has always been focussed on the customer needs. Thanks to decades of experience and the high specialization acquired in the automotive sector, C. T. Centro Tornitura is able to follow and collaborate with the customer during the entire product development and production cycle to guarantee the best quality / price ratio.

C.T. Centro Tornitura has a technical office equipped with advanced 3D CAD / CAM software for designing, drawing and optimizing even complex mechanical parts and components. The passage from the design phase to the production phase is managed through dedicated software to guarantee a precise control of each production step.

C. T. Centro Tornitura has modern CNC machines offering a wide variety of operations, including turning, milling and other machining operations, according to the customer needs. We machine various types of materials such as: steel, stainless steel, aluminum, brass, copper, special alloys, etc.

Thanks to the well-proven quality system, all the processes carried out at our company undergo accurate checks, carried out with regularly controlled and certified measuring instruments and with 3D coordinate measuring machines, with which we are able to monitor all the production steps and produce the statistical control documentation for the customer.

C.T. Centro Tornitura collaborates with experienced and qualified external suppliers for the realization of heat and galvanic treatments.

C.T. Centro Tornitura has always paid attention to the quality of its products and processes. Our activity is certified according to the latest ISO 9001: 2015, IATF 16949: 2016, UNI EN ISO 14001: 2015 standards.